If you have ever wondered how is the product design process, today we bring you the answer. By our side, we want to bring a small contribution to a quite unknown subject regarding to the general audience, and for this purpose we will take a model of sunglasses that can be considered a design milestone as an example. So, how does it all begin?

The first step is the initial briefing. Here, the customer sets out his or her needs and the technical and economic requirements, as well as the aesthetic constraints that he or she wants to add to the product. The initial timing and the design process stages that must be completed in a timely manner are established. This is part of the preliminary engineering stage, and thus the feasibility of the project is reviewed as a previous step to any design proposal.

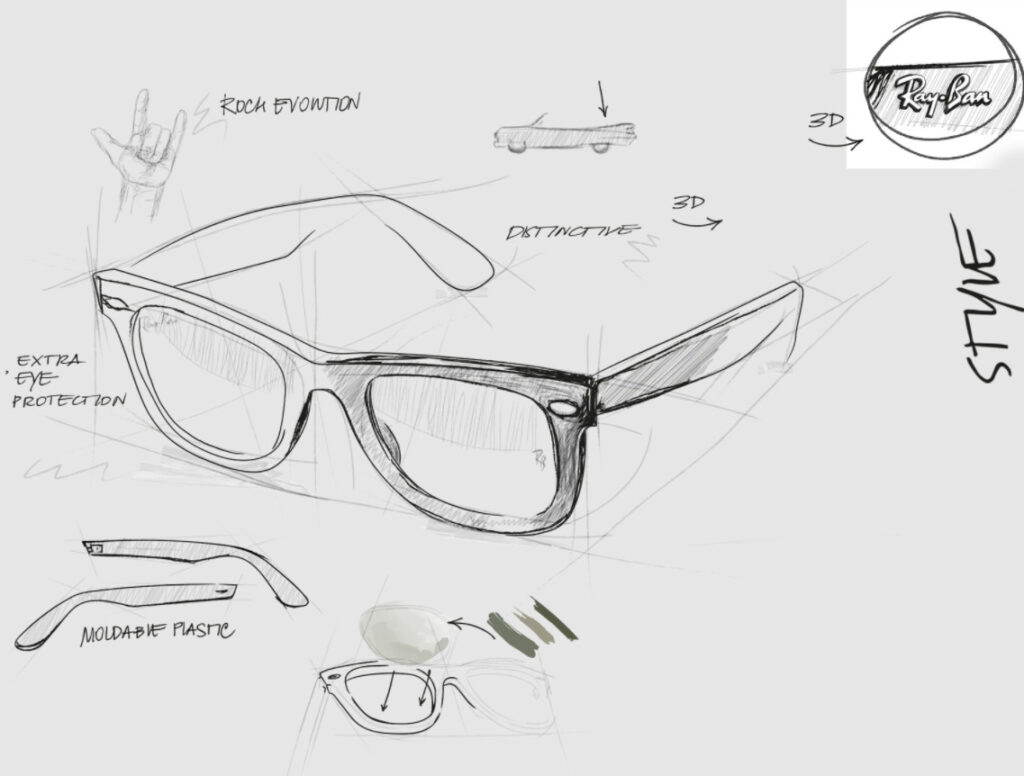

From this point on, the concept stage begins. In this moment, the product aesthetics and the connotations we want the user to feel are properly reviewed to a greater extent. It is common to use tools such as sketching or rendering to go deep in this sense and to better express the designer’s initial ideas. It is usual to offer a series of design proposals to the customer, always taking into account the manufacturing process and the functional requirements that will be added afterwards to the product design.

Once a design concept is decided, the detailed design or manufacturable design of the product needs to be worked on. Since the beginning of the 20th century, the manufacture of industrial products has been programmed following specific assembly lines for each case and according to the established manufacturing process. In that regard, a number of design features must also be applied depending on the attributes that we want to incorporate into the product.

When the product design is sufficiently mature, then the prototyping stage finally starts. This is the moment to use the additive manufacturing techniques to physically see the state of the product, its functional characteristics or the design lines that we did apply previously. The prototypes can also be used for initial quality tests and to study the mechanical behavior as well. It is common for design changes to arise from this stage, and it is true that what is seen through a screen is not the same as the real model.

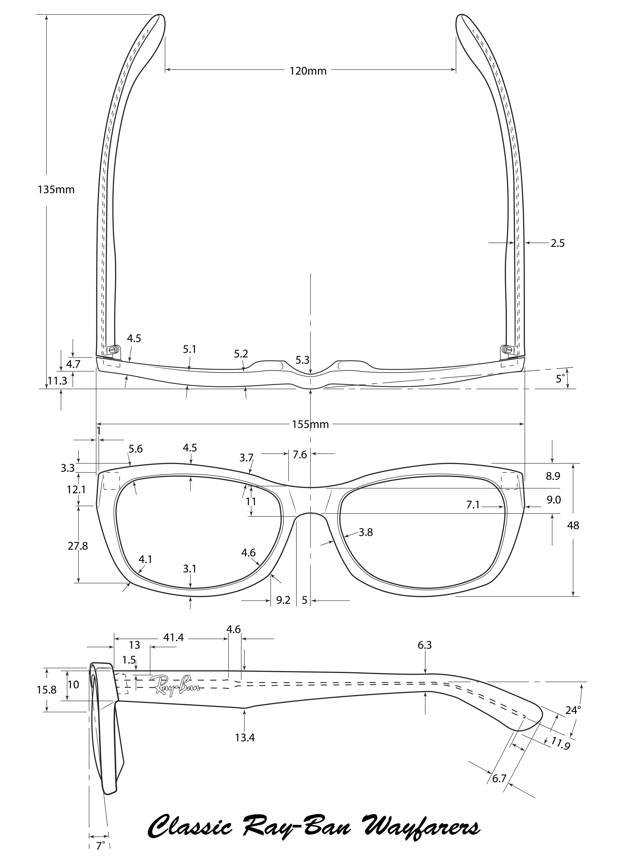

Finally, when the model has been optimized, the design meets the initial specifications and the customer is completely satisfied, it is time for mass production. For this purpose, it is necessary to prepare detailed and manufacturing drawings of the product, as well as the design of manufacturing support tools to complete the process engineering.

Once this point is reached, it is usual to find some last minute modification in the product geometry due to some adjustment required by the manufacturer or according to the quality department criteria when the first parts are produced prior to the final manufacturing status.

At Round Corner, we are experts in product design from the preliminary engineering stage to industrialization. If you have any questions or you would like to shape an idea, please do not hesitate to contact us.