Product design is an integral part of the product development process. It is one of the core activities in the research and development (R&D) stage and involves the creation of designs for improved efficiencies, increased functionality and improvement in manufacturing processes. In this article, we will discuss the product design process, product systems, how to address sustainability issues in product design, and its importance in the product development life-cycle.

Product design is a very challenging profession. It is not as easy as it seems and requires in-depth knowledge, understanding, and experience. Design processes and models also play an important role in product development. One should be aware of both the process of designing products and the use of production systems which enable you to deliver high-quality products on time, within budget and at low manufacturing cost. Product development aims to create a product that is of good quality and value for the intended use. The product design process may be long and complex, so it needs to be planned and organized properly. To meet this objective very well, designers or product engineers need to know the manufacturing process as well.

Product Design Process and Product Systems:

The design process begins with a need or problem the company wants to solve. The company will then gather information about their customers, competitors, and the environment in which they plan to sell its product. This information is used to create a prototype of the product and evaluate whether it meets the needs of its customers. The design process is the first stage of a product’s life cycle.

Product design is a process that involves three major steps: ideation, research and development (R&D), and evaluation.

- Ideation is when the team starts thinking about what they want to develop. It’s a brainstorming session where everyone contributes ideas for new products or services. This can be hard because there are so many possibilities!

- Research and development (R&D) are where engineers work to figure out how to make the product an actual product. They study consumer behaviour, market trends, and more to find out how people will use them.

- Evaluation is when you go back through your R&D process and see if your idea has made it into reality! You’ll be able to evaluate whether people will like the product or not, whether it’s worth spending money on making it into a real thing, etc…

Product systems are the design, manufacturing, and engineering of products that are produced in large quantities. Many products are made by combining multiple individual systems. A product system is a set of interrelated processes that create a product, such as a car or a computer. The principal goal of product systems is to reduce waste and cost by minimizing downtime and maximizing efficiency across all stages of product development. Product systems can be used to create value by improving quality, reducing waste, and increasing customer satisfaction. Product systems are a way to design products that can be manufactured, engineered, and operated sustainably.

In some cases, they can design product systems from the ground up to be more efficient and cost-effective. For example, if a designer wants to create a new type of vehicle, she might consider using an existing platform as a base for her design. In this case, she would need to redesign several aspects of the vehicle—including how it is built and operated—to make it more efficient. Another type of product system involves taking an existing product or process and redesigning it so that it is more energy efficient or environmentally friendly. They often referred this type of design to as “upcycling.”

Product systems are modular, scalable, and configurable. They are designed to be highly adaptable to a variety of applications and can be used in different industries. A set of interfaces that provide the means for data exchange connects the components. Product systems may consist of several parts such as an engine, a gearbox, an axle and wheel assembly etc., which are all integrated to create a functional whole. Some examples of product systems include automobiles, aircraft, computers, etc., which use these components as part of their design.

It’s not enough to just design a product. You also need to design a manufacturing process, so that it can be made efficiently and safely. Then you need to engineer it so that they can produce it in high volumes. Finally, you need to figure out how the product will perform in the real world—and that means making sure that your design is sustainable as well as functional.

In other words, no matter what kind of product you’re designing, it’s important to think about everything from conception through production.

Applying systems thinking to the product design process.

In today’s world, products are designed and engineered increasingly complexly. This has led to a need for more advanced product design processes that account for the complexity of real-world situations.

One of the most commonly used methods for managing complexity is systems thinking. Systems thinking involves breaking down a complex system into its constituent parts, and then analyzing how each part interacts with other parts and how those interactions change over time. It can be used to identify where problems might occur and how to avoid them, as well as how to maximize the efficiency of the system. When applied to product design, systems thinking helps designers understand what type of products people want, what they need to use these products effectively, and how these needs are affected by changes within society or technology. It also provides insight into how users will interact with products over time so that they can be developed accordingly.

At Round corner, we believe that systems thinking is key for product design. To design a product that meets customer needs and expectations, it is essential to consider the context in which it will be used. To do so, we need to step back from our product and think about how it fits into a larger system.

Addressing sustainability issues in product design.

The idea of designing for sustainability is not new—it’s been part of engineering practice since the early 1900s. However, it wasn’t until recently that designers began to take into account the long-term impacts of their designs on the world around them and on humanity itself. The design engineer and product designers must be able to think through the entire life cycle of a product or system and make sure that they have taken into account all factors that can impact its sustainability. This includes making sure that their design will stand up to environmental stressors such as heat and cold, humidity, sunlight exposure, corrosion and dust.

Sustainability is a key consideration in product design. It’s not just about ensuring that the design process doesn’t impact the environment—it’s also about ensuring that the end product is sustainable, which means it meets an objective standard of being good for the environment.

Sustainable products are those that maintain or improve their performance over time and do not harm the environment or people who use them. Sustainable products can be used in multiple ways, from being built to last for a long time, to having a low environmental impact on materials used during manufacturing and disposal, to creating less waste during production and after use (such as through recycling).

Conclusively, Design is not only about creating great product features or commercial value, it is also about improving the world we live in by making products that are sustainable and friendly to our environment. The wonderful thing about design is that it saves time, money and resources. A good design solution is to identify the risks of the product system early in the process and analyze whether they are design risks or production risks.

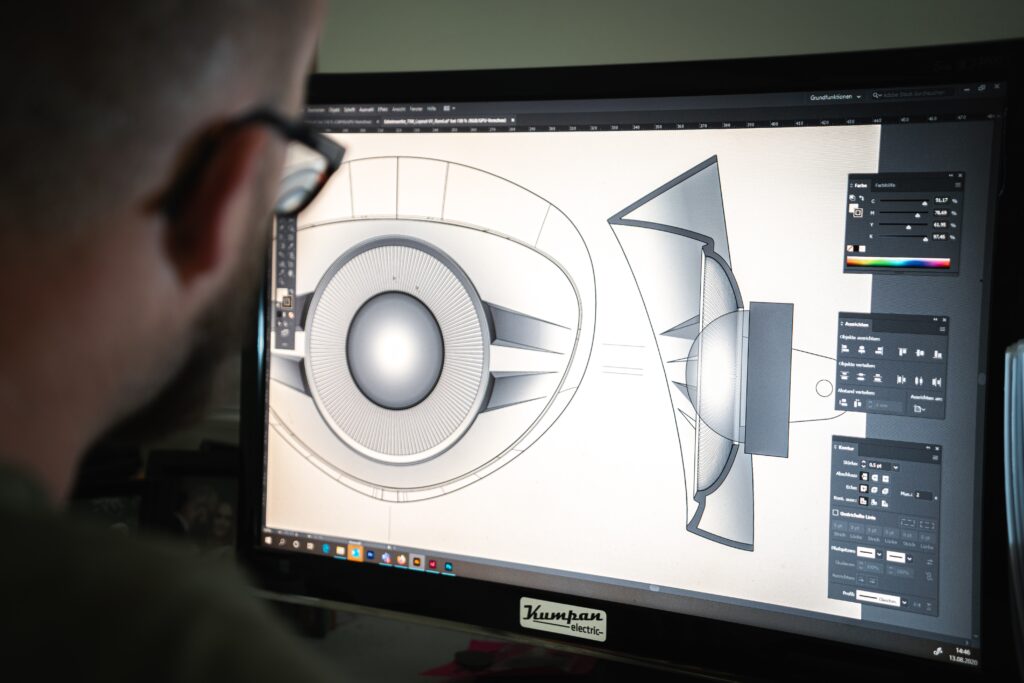

To take on a problem as complex as the electric scooter, we needed to start at the beginning and understand the whole scope of the project. To do this, you will need to consider how to model components (elements) of your proposed product system and how they could change its performance. Also, consider how the aspects might come together in a larger structure.

We believe at the Round Corner that design is a key to solving business problems and that it should be done systematically. We believe this because it allows us to create products that are both beautiful and useful, which makes them more valuable than those that are not.